Varex Imaging Corporation

-

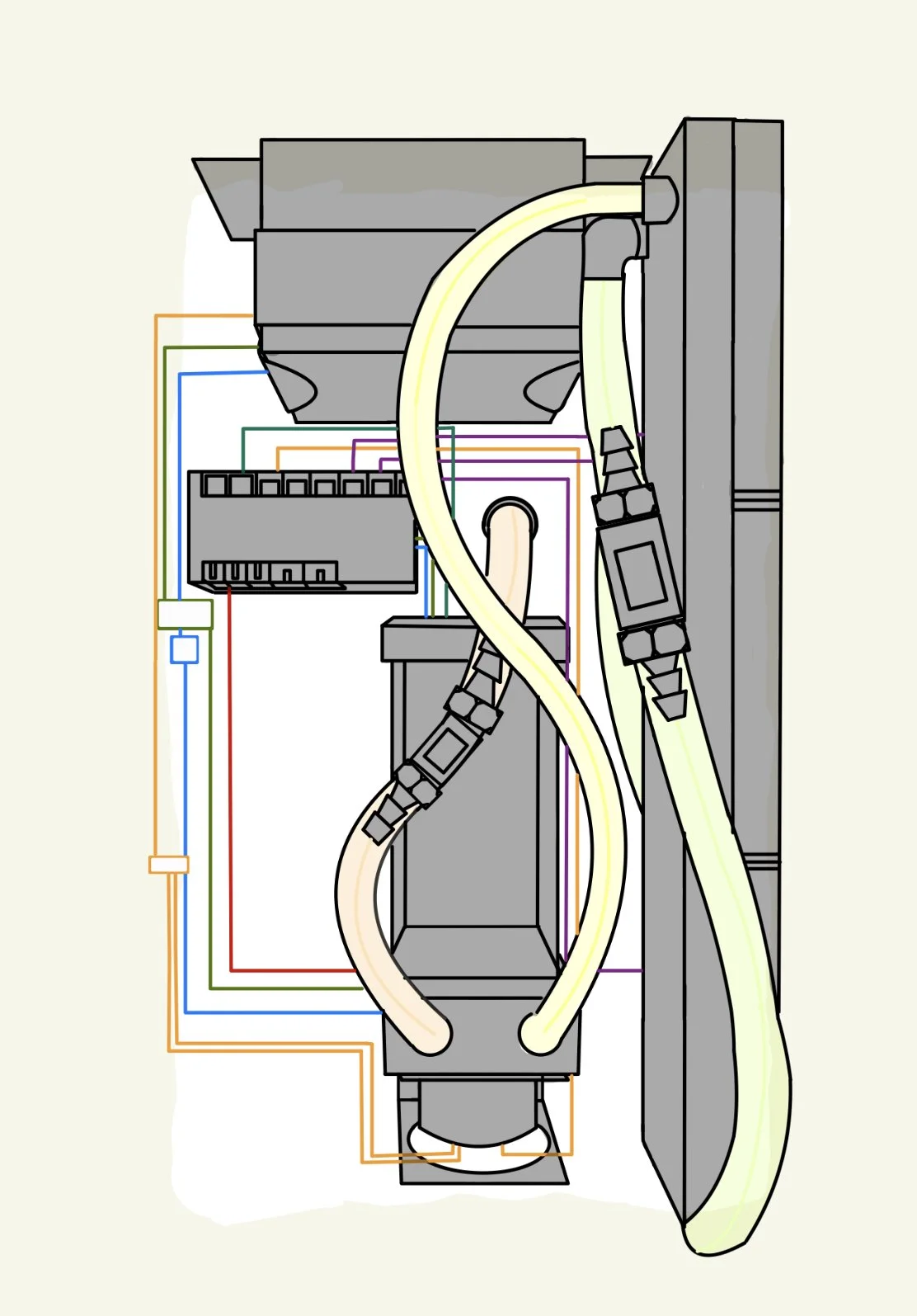

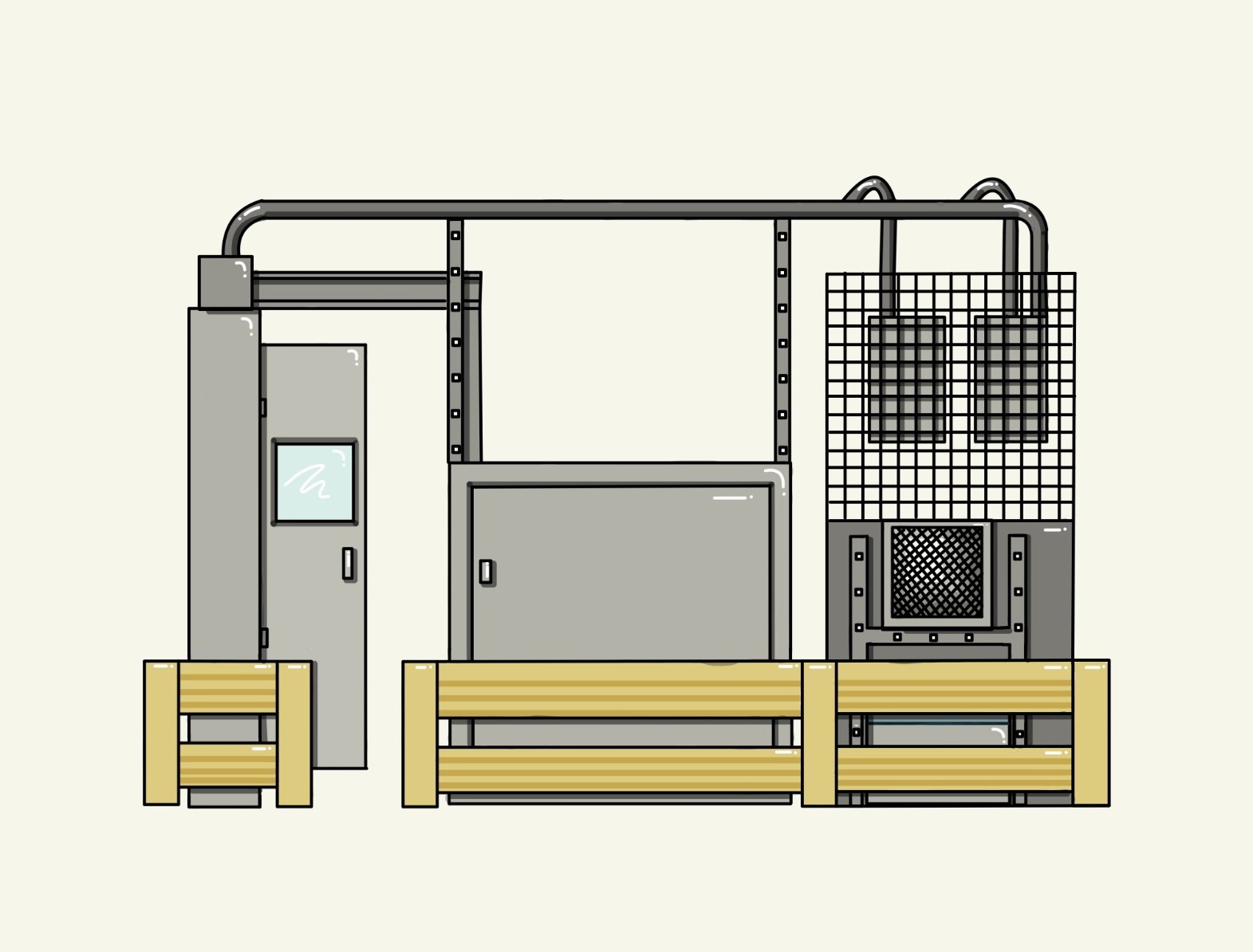

• Lead first-ever company effort to develop a subsystem (composed of x-ray tube, generator, controller and heat exchanger) with intent to be offered to customers. Drove effort by leading a cross-functional team, establishing requirements of individual components and their interfaces, wrote and managed Program Plan, Verification Plan, and Validation Plan.

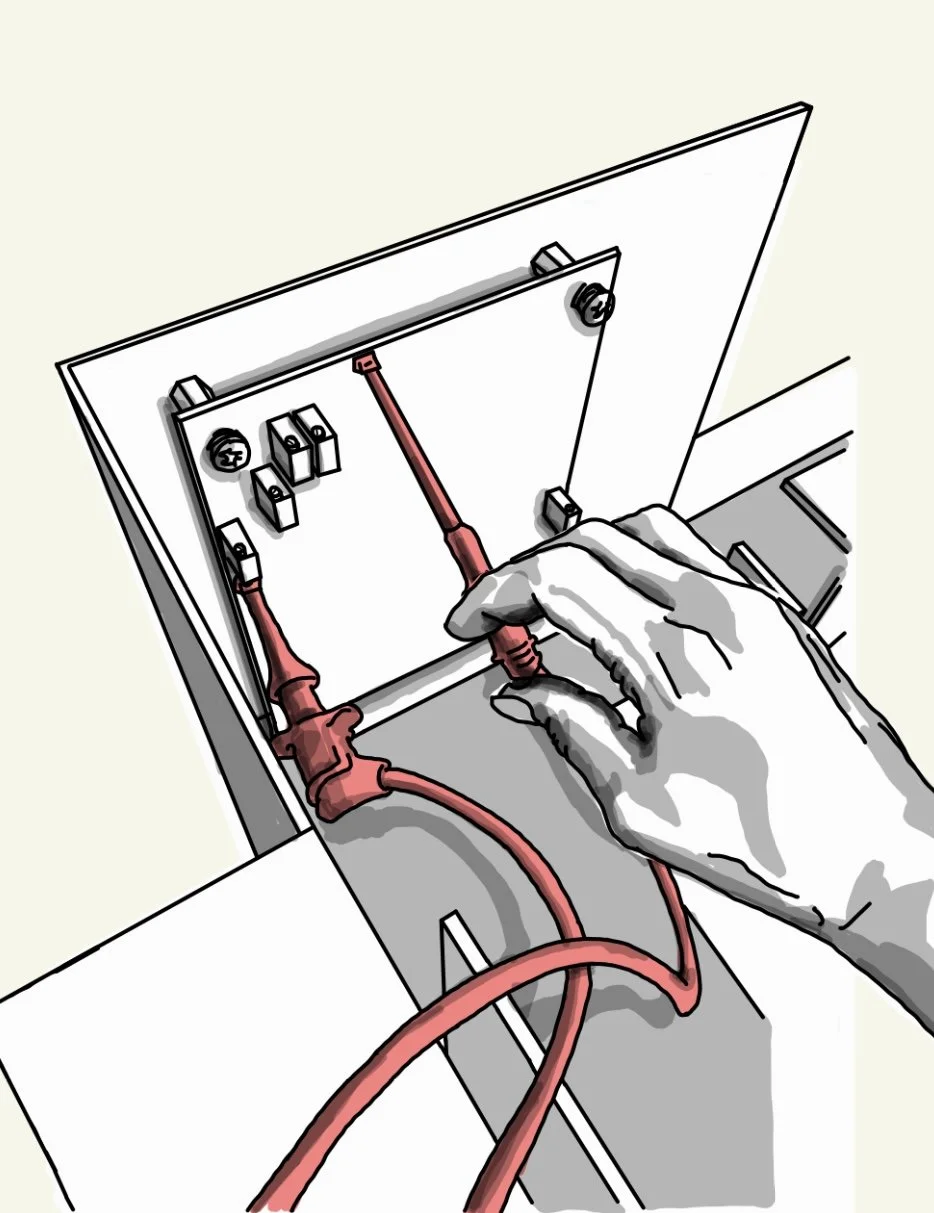

• Lead a root cause corrective action (RCCA) testing campaign on 45 x-ray tubes to address tubes failing in the field; identified cause as a newly implemented component. Traveled to customer site and operated equipment to demonstrate use. Documented site-specific application of tubes with detailed diagrams.

• Wrote six internal/external work instructions on the safe operation and testing of newly developed high voltage generator/x-ray tube/cooler/controller subsystem.

-

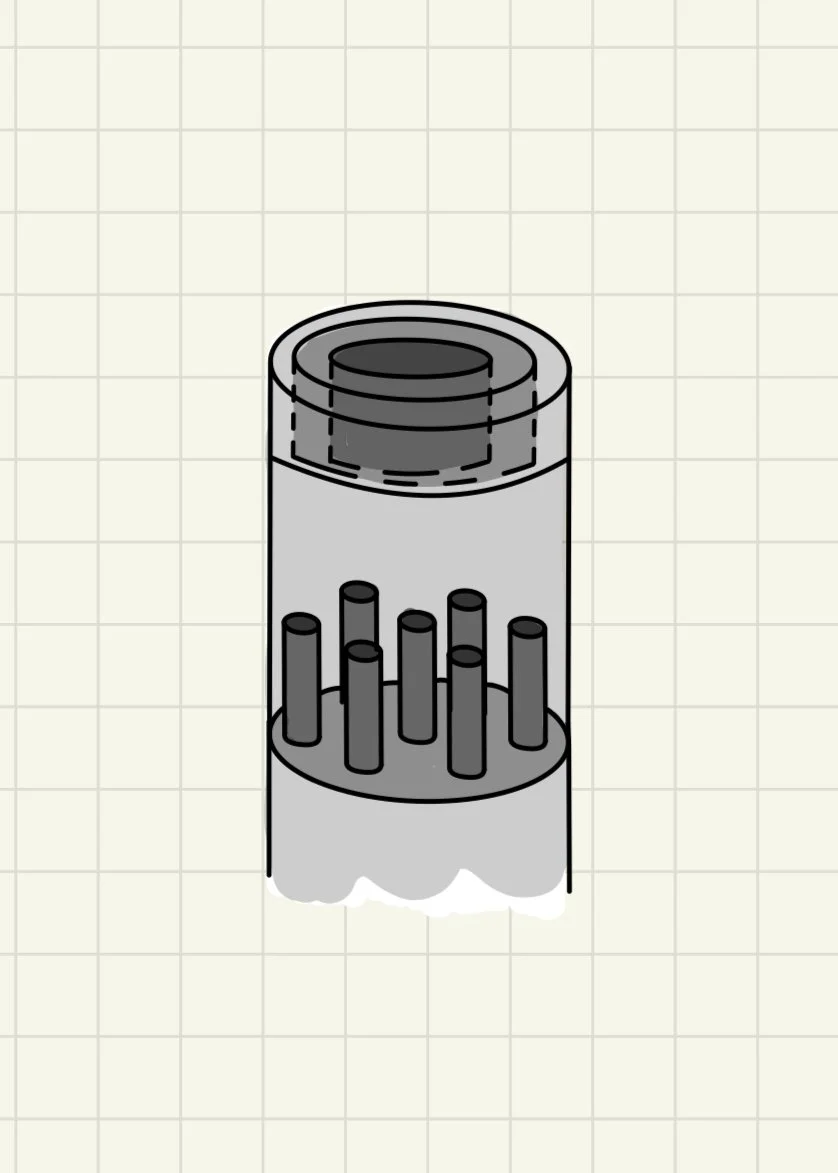

• Lead an RCCA test campaign on x-ray tubes that were failing acceptance test; identified the cause as a change in the manufacturing process.

• Developed and implemented new cleaning method, including prototyping fixture and gaining temporary change approval (TCA).

• Verified and validated new production process; lead training of cross-functional technician teams for new cleaning and outgassing methods.

-

• Built heat exchanger prototype for the purpose of specifying radiator and pump design. Used both FEA and CFD during design process to improve accuracy.

• Performed material recovery efforts for high-value and high toxicity items, reducing corporate environmental impact and improving bottom line by saving the company $2k per x-ray tube.